Eli nqaku liza kwazisa iimbono zoyilo kunye nenkqubo yokucubungula isigqubuthelo sebhokisi yesidlo sasemini yeplastiki ngokweenkcukacha, kunye nesakhiwo samalungu eplastiki, izixhobo zohlalutyo olubanzi, uyilo olufanelekileyo lobuchwephesha bokubumba.

Amagama aphambili: isitofu sokungunda;Ibhokisi yesidlo sasemini.Inkqubo yokubumba

Icandelo lokuQala: Uhlalutyo lwenkqubo yamalungu eplastiki kunye nokhetho oluphambili lomatshini wokutofa

1.1Imathiriyeli ekrwada kunye nohlalutyo lokusebenza kwibhokisi yesidlo sasemini seplastiki

Le bhokisi yesidlo sasemini yeplastiki yimveliso yeplastiki eqhelekileyo kubomi bemihla ngemihla, ikakhulu esetyenziselwa ukubamba ukutya.Ukuqwalasela ngokukodwa ukusetyenziswa kwayo, uhlalutyo olubanzi lwentsebenzo yeeplastiki ezahlukeneyo, ukukhethwa kwezinto eziphathekayo zepolypropylene (PP).

I-Polypropylene (iplastiki ye-PP) luhlobo lobuninzi obuphezulu, akukho tyathanga elisecaleni, i-crystallization ephezulu ye-polymer ehambelanayo, ineempawu ezintle ezibanzi.Xa ingenambala, imhlophe i-translucent, i-waxy;Ilula kune-polyethylene.Ukungafihli kukwangcono kune-polyethylene.Ukongezelela, ubuninzi bepolypropylene buncinci, ubunzima obuthile be-0.9 ~ 0.91 grams / cubic centimeter, amandla okuvelisa, ukuqina, ukuqina kunye nokuqina, amandla oxinzelelo aphezulu kune-polyethylene.Ubushushu bayo bokubumba yi-160 ~ 220 ℃, ingasetyenziswa malunga ne-100 degrees, kwaye ineempawu ezilungileyo zombane kunye nokugquma okuphakamileyo okuphezulu akuchaphazeli ukufuma.Izinga layo lokufunxa amanzi liphantsi kune-polyethylene, kodwa kulula ukunyibilika ukuphuka komzimba, ukudibanisa ixesha elide kunye nentsimbi eshushu kulula ukubola, ukuguga.I-fluidity ilungile, kodwa isantya sokwenza i-shrinkage yi-1.0 ~ 2.5%, isantya sokunciphisa sikhulu, esilula ukukhokelela kumngxuma wokucutha, i-dent, deformation kunye nezinye iziphene.Isantya sokupholisa sePolypropylene siyakhawuleza, inkqubo yokugalela kunye nenkqubo yokupholisa kufuneka ipholise kancinane, kwaye inikele ingqalelo ekulawuleni ubushushu bokubumba.Ubukhulu bodonga lweengxenye zeplastiki kufuneka bufanane ukuphepha ukungabikho kweglue kunye ne-Angle ebukhali ukukhusela uxinzelelo loxinzelelo.

1.2Uhlalutyo lwenkqubo yokubumba ibhokisi yesidlo sasemini seplastiki

1.2.1.Uhlalutyo lwesakhiwo samalungu eplastiki

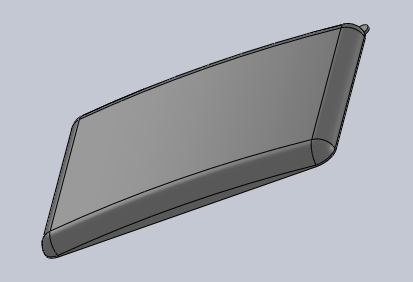

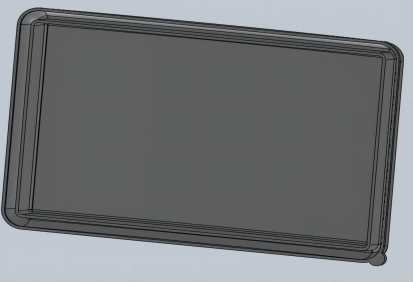

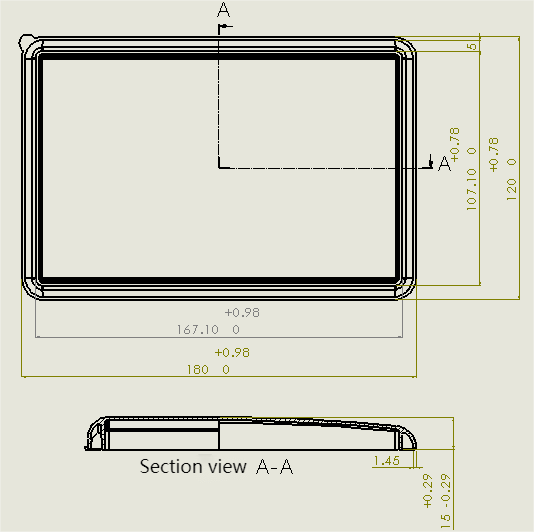

Ubukhulu bodonga olucetyiswayo lwepolypropylene iinxalenye zeplastiki ezincinci yi-1.45mm;Ubungakanani obusisiseko bebhokisi lesidlo sasemini yi-180mm×120mm×15mm;Thatha ubungakanani bodonga lwangaphakathi lwesigqubuthelo sebhokisi lesidlo sasemini: 107mm;Umahluko phakathi kweendonga zangaphakathi nangaphandle: 5mm;Ikona ejikeleziweyo yodonga lwangaphandle yi-10mm, kwaye ikona ejikeleziweyo yodonga lwangaphakathi ngu-10/3mm.Ikona enye yebhokisi yebhokisi inomphathi we-annular kunye ne-radius ye-4mm.Ngenxa yokuba iinxalenye zeplastiki zizikhongozeli ezibhityileyo ezinodonga, ukuze kuthintelwe ukungabikho kokuqina kunye namandla okubangelwa yi-deformation yamalungu eplastiki, ngoko ke umphezulu wamacandelo eplastiki uyilwe njengesangqa se-arc ephezulu ye-5mm.

1.2.2.Uhlalutyo oluchanekileyo lomgangatho wamalungu eplastiki

Imilinganiselo emibini yesigqubuthelo sebhokisi yesidlo sasemini ineemfuno zokuchaneka, ezizezi, i-107mm ne-120mm, kunye nemfuno yokuchaneka yiMT3.Ekubeni ubungakanani bangaphandle bamacandelo eplastiki buchaphazeleka ngokunyamezelwa kwemilinganiselo yenxalenye eshukumayo yokubumba (efana ne-flying edge), uhlobo lokunyamezela lukhethwa njengebakala B. Ukuba inqanaba lokunyamezela alifunwa, i-MT5 ikhethiwe. .

1.2.3.Uhlalutyo lomgangatho womphezulu wamalungu eplastiki

Ukuchaneka komphezulu we-lunchbox cover ayikho phezulu, kunye noburhabaxa bomphezulu i-Ra yi-0.100 ~ 0.16um.Ke ngoko, ukubunjwa kwenaliti yendawo yokwahlulahlula kwindawo enye yembaleki yesango inokusetyenziselwa ukuqinisekisa ukuchaneka komphezulu.

1.2.4.Iimpawu zezinto eziphathekayo kunye nomthamo kunye nomgangatho weengxenye zeplastiki

Buza iipropati eziphathekayo zeplastiki ye-PP (kubandakanywa imodyuli e-elastic, umlinganiselo we-Poisson, ubuninzi, amandla okuxinana, ukuqhutyelwa kwe-thermal kunye nobushushu obuthile) kwi-SolidWorks, kwaye usebenzise isofthiwe ye-SolidWorks ukubala idatha yamacandelo eplastiki (kubandakanya ubunzima, umthamo, indawo ephezulu kunye neziko womxhuzulane).

1.3 Qinisekisa iiparamitha zenkqubo yokubumba yamacandelo eplastiki

Kwinkqubo yokubumba inaliti, ubushushu be-cylinder kunye nombhobho uya kuchaphazela iplastiki kunye nokuhamba kweplastiki, iqondo lokushisa lokungunda liya kuchaphazela ukuhamba kunye nokupholisa kokubunjwa kweplastiki, uxinzelelo kwinkqubo yokubumba inaliti luya kuchaphazela ngqo iplastiki yeplastiki kunye neengxenye zeplastiki ezisemgangathweni.Ukuveliswa kwimeko yokuqinisekisa umgangatho wamacandelo eplastiki kuya kuzama ukunciphisa umjikelo wokubunjwa kwamalungu eplastiki, ixesha lokutofa kunye nexesha lokupholisa linempembelelo eqinisekileyo kumgangatho wamacandelo eplastiki.

Imibuzo emayiqwalaselwe xa uyilwa:

I-1) Ukusetyenziswa ngokufanelekileyo kwe-stabilizers, i-lubricant ukuqinisekisa ukusebenza kwenkqubo ye-PP yeplastiki kunye nokusetyenziswa kweengxenye zeplastiki.

2) I-Shrinkage, indentation, deformation kunye nezinye iziphene kufuneka zithintelwe ngexesha loyilo.

I-3) Ngenxa yesantya sokupholisa ngokukhawuleza, qwalasela ukutshatyalaliswa kobushushu benkqubo yokugalela kunye nenkqubo yokupholisa, kwaye ubeke ingqalelo ekulawuleni ukushisa okwenza.Xa iqondo lokushisa lokubunjwa lingaphantsi kwama-degrees angama-50, iinxalenye zeplastiki aziyi kuhamba kakuhle, kuya kuba ne-welding embi, ukushiya amanqaku kunye nezinye izinto;Ngaphezulu kweedigri ze-90 zithandeka kwi-warp deformation kunye nezinye iziganeko.

4) Ubukhulu bodonga lwamacandelo eplastiki buya kufana nokuphepha ukuxinzelela uxinzelelo.

1.4 Imodeli kunye neenkcukacha zomatshini wokubumba inaliti

Ngokweeparamitha zenkqubo yokubumba yamacandelo eplastiki, ukhetho lokuqala lomatshini wokubumba we-G54-S200/400 wemodeli yasekhaya,

Icandelo leSibini: Uyilo lolwakhiwo lweplastiki yesidlo sasemini yesigqumathelo sokungunda kwesitofu

2.1 Ukumiselwa kwendawo yokwahlulahlula

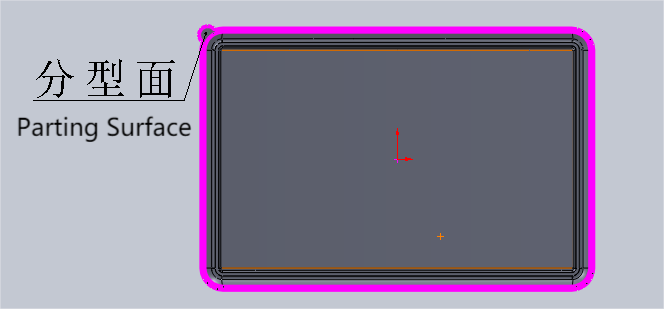

Ubume obusisiseko kunye nemeko yokudilizwa kweengxenye zeplastiki kufuneka ziqwalaselwe xa ukhetha indawo yokwahlula.Imigaqo yoyilo lomphezulu wokwahlula imi ngolu hlobo lulandelayo:

1. Umphezulu wokuhlukana kufuneka ukhethwe kwi-contour ephezulu yecandelo leplastiki

2. Ukukhethwa kwendawo yokwahlula kufuneka kube lula ukudilizwa ngokugudileyo kwamalungu eplastiki

3. Ukukhethwa kwendawo yokwahlula kufuneka kuqinisekise ukuchaneka komgangatho kunye nomgangatho womphezulu wamalungu eplastiki kunye neemfuno zabo zokusetyenziswa.

4. Ukukhethwa kwendawo yokwahlula kufuneka kuhambisane nokucubungula kunye nokulula ukubumba

5. Nciphisa indawo yokubonisa imveliso kwicala le-clamping

6. Undoqo omde kufuneka ubekwe kwicala lokuvula ifa

7. Ukukhethwa kwendawo yokwahlula kufuneka kube lula ukukhupha

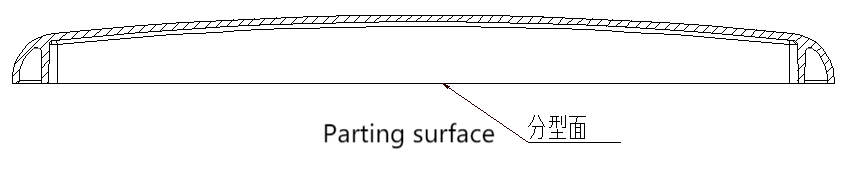

Ukushwankathela, ukuze kuqinisekiswe ukudilizwa okugudileyo kwamalungu eplastiki kunye neemfuno zobugcisa zamacandelo eplastiki kunye nokuveliswa okulula kokungunda, indawo yokwahlula ikhethwa njengomgangatho ophantsi webhokisi lebhokisi lesidlo sasemini.Njengoko kubonisiwe kuMfanekiso ongezantsi:

2.2 Ukumiselwa kwenombolo ye-Cavity kunye nokwakheka

Ngokweemfuno zoyilo zenxalenye yeplastiki yoyilo lwencwadana, iinxalenye zeplastiki iimpawu zesakhiwo sejometri kunye neemfuno zokuchaneka komgangatho kunye neemfuno zezoqoqosho zemveliso, zimisela ukusetyenziswa komgodi wokubumba.

2.3 Uyilo lwenkqubo yokugalela

Olu yilo lwamkela inkqubo yokugalela eqhelekileyo, kwaye imigaqo yayo yoyilo imi ngolu hlobo lulandelayo:

Gcina inkqubo imfutshane.

Ukuphuma kufuneka kube kuhle,

Thintela ukuguqulwa okungundoqo kunye nokufaka ukufuduswa,

Ukuthintela ukuguqulwa kwe-warping yamacandelo eplastiki kunye nokubunjwa kwamabala abandayo, amabala abandayo kunye nezinye iziphene kumphezulu.

2.3.1 Uyilo lwetshaneli engundoqo

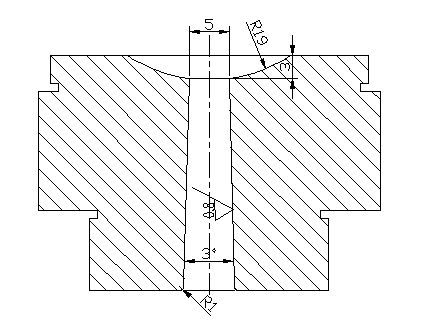

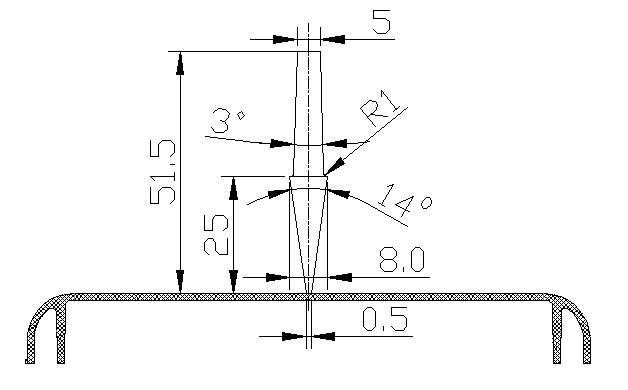

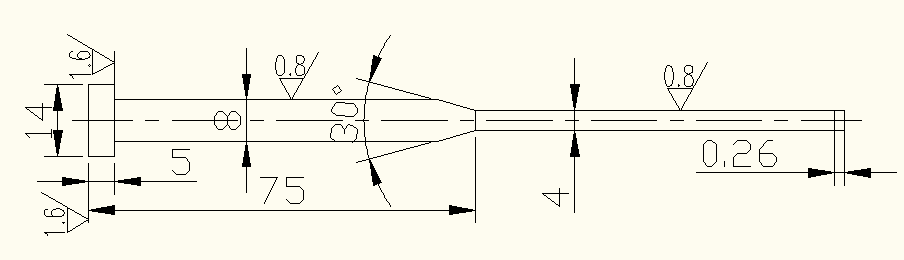

Umjelo oyintloko wenzelwe ukuba ube yi-conical, kunye ne-cone Angle α yi-2O-6O, kunye ne-α = 3o.Ubunzima bomphezulu wejelo lokuhamba i-Ra≤0.8µm, i-outlet ye-channel ephambili yinguqu ye-fillet, ukwenzela ukunciphisa ukuchasana kokuhamba kwezinto ukuya kwinguqu, i-fillet radius r = 1 ~ 3mm, ithathwa njenge-1mm. .Uyilo oluphambili lwetshaneli ngolu hlobo lulandelayo;

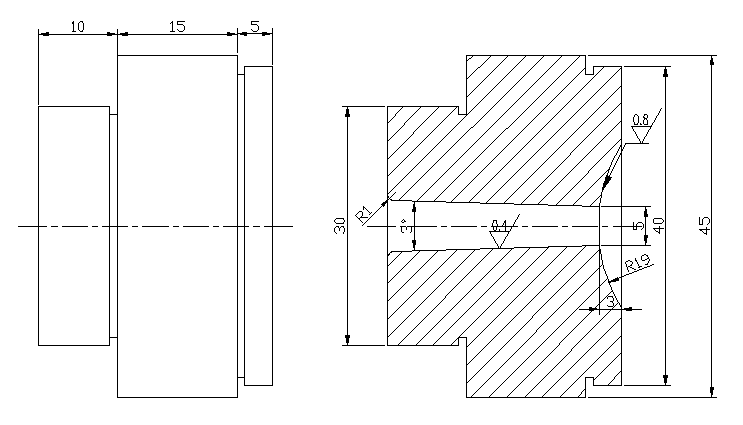

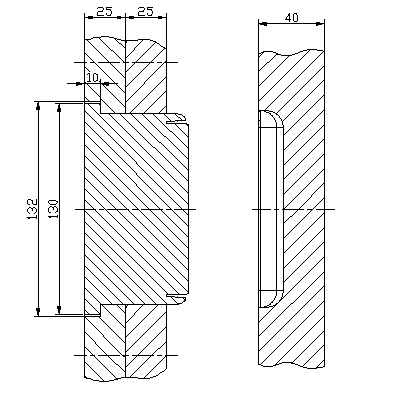

Ulwakhiwo lomkhono wesango luyilwe lube ngamacandelo amabini kusetyenziswa umkhono wesango kunye nendandatho yokumisa, egxininiswe kwipleyiti yesitulo esisisigxina sokufa ngendlela yesinyathelo.

Ububanzi besiphelo esincinci somkhono wesango ngu-0.5 ~ 1mm omkhulu kunombhobho, othathwa njenge-1mm.Ekubeni umphambili wesiphelo esincinci yingqukuva, ubunzulu bayo buyi-3 ~ 5mm, ethathwa njenge-3mm.Ekubeni i-sphere ye-nozzle yoqhagamshelwano lomatshini wokutofa kwaye ihambelana nokubumba kule ndawo, ububanzi be-sphere ye-channel engundoqo kufuneka ibe yi-1 ~ 2mm enkulu kunombhobho, othathwa njenge-2mm.Ifomu yokusetyenziswa kunye neeparamitha zomkhono wesango ziboniswe ngezantsi:

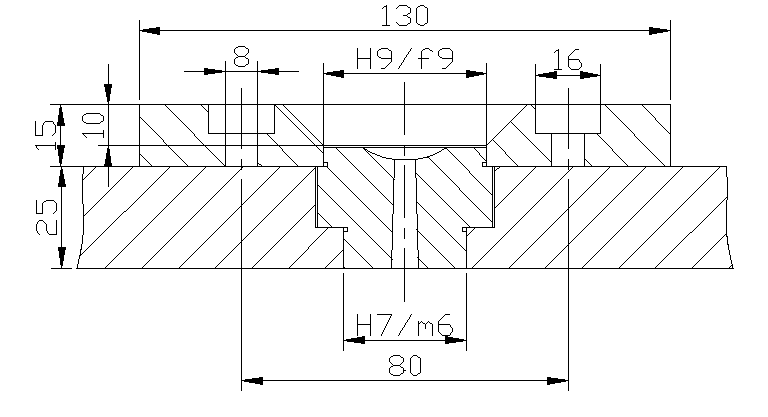

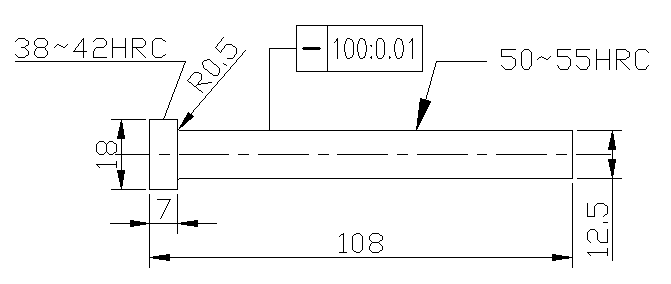

I-H7/m6 inguqu elungelelanisiweyo yamkelwa phakathi komkhono wesango kunye nethempleyithi, kwaye i-H9/f9 efanelekileyo yamkelwa phakathi komkhono wesango kunye neringi yokubeka.Iringi yokubeka ifakwe kwindawo yokubeka i-template esisigxina yomatshini wokujova ngexesha lofakelo kunye nokulungiswa kwe-mold, esetyenziselwa ukufakwa kunye nokubeka i-mold kunye nomatshini wokujova.I-diameter yangaphandle yeringi yokubeka i-0.2mm encinci kunomngxuma wokumisa kwi-template esisigxina yomatshini wokutofa, ngoko yi-0.2mm.Ifomu emiselweyo yomkhono wesango kunye nobukhulu beringi yokumisa iboniswe ngezantsi:

2.3.2 Shunt uyilo lwetshaneli

Ngenxa yokuba uyilo lungumngxuma wokungunda, umphezulu wokwahlula kumzantsi wesigqubuthelo sebhokisi, kunye nokhetho lwesango lohlobo oluthe ngqo lwesango, ngoko ke i-shunt ayinyanzelekanga ukuyila.

2.3.3 Uyilo lwesango

Ukuqwalasela iimfuno zokubunjwa kweengxenye zeplastiki kunye nokulungiswa kwe-mold kukulungele okanye akunjalo kwaye ukusetyenziswa kwangempela kwimeko, ngoko ukuyila kwendawo yesango kukhethwe njengeziko eliphezulu lebhokisi lebhokisi lesidlo sasemini.Ubukhulu besango lendawo ngokuqhelekileyo yi-0.5 ~ 1.5mm, kwaye ithathwa njenge-0.5mm.I-Angle α idla ngokuba ngu-6o ~ 15o, kwaye ithathwa njenge-14o.Uyilo lwesango luboniswe ngezantsi:

2.4 Uyilo lomngxuma obandayo kunye nentonga yokutsala

Ke ngoko, uyilo sisingundo kunye nomngxuma, isango lesango lokugalela ngokuthe ngqo, ngoko umngxuma obandayo kunye nentonga yokutsala ayifuni ukuyilwa.

2.5 Uyilo lwamalungu okwenza amalungu

2.5.1Ukuzimisela kwesakhiwo sokufa kunye ne-punch

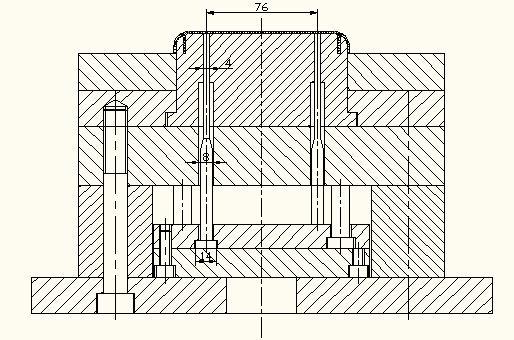

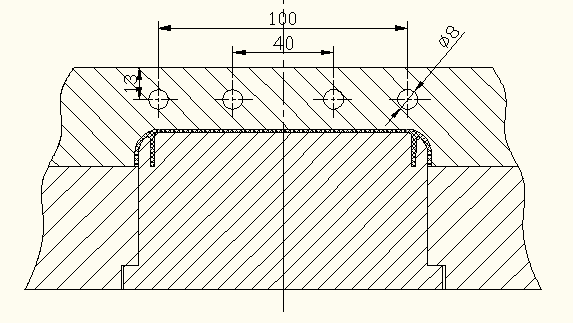

Ngenxa yokuba yinxalenye yeplastiki encinci, umngxuma, kwaye ukwenzela ukuba kusetyenzwe kakuhle, ukuchithwa okufanelekileyo, kodwa kunye nokuqinisekisa ubume kunye nobungakanani bokuchaneka kwamalungu eplastiki, uyilo lwe-convex epheleleyo kunye nokukhethwa kwe-concave kufa kuyo yonke.I-convex die iqhutywe yindlela yokucubungula eyahlukileyo, kwaye emva koko icinezelwe kwi-template ngenguqu ye-H7 / m6.Umzobo weskimu woyilo lwesakhiwo seconvex kunye neconcave die ilandelayo:

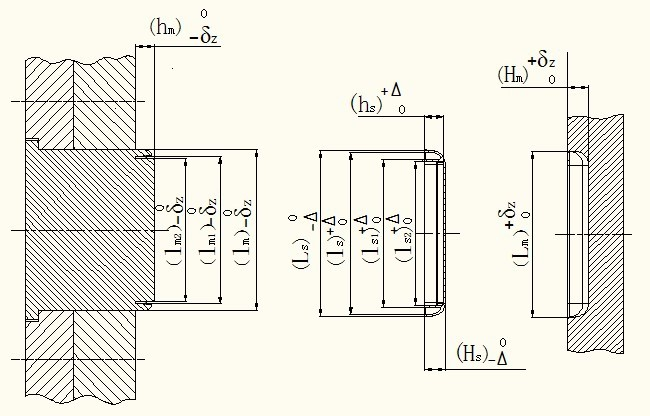

2.5.2Uyilo kunye nokubalwa komgobho kunye nesakhiwo esingundoqo

Ubudlelwane phakathi kobungakanani bokusebenza kwenxalenye yokubumba kunye nobukhulu benxalenye yeplastiki buboniswe ngezantsi:

2.6 Ukukhethwa kwesakhelo sokungunda

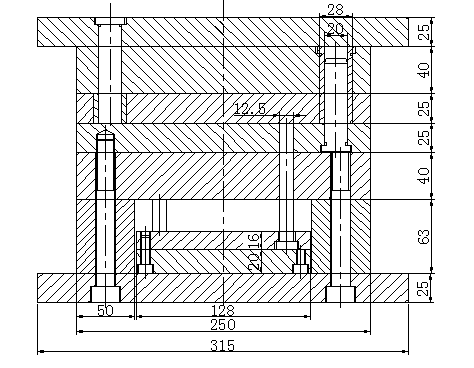

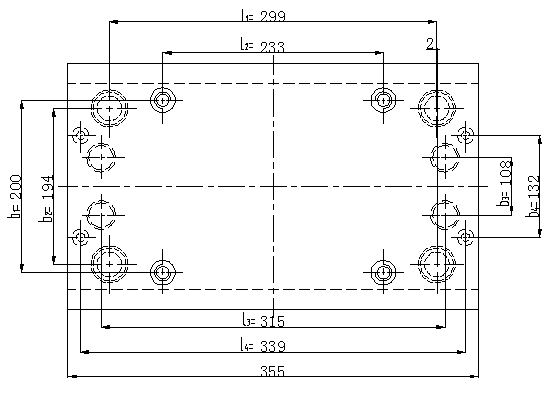

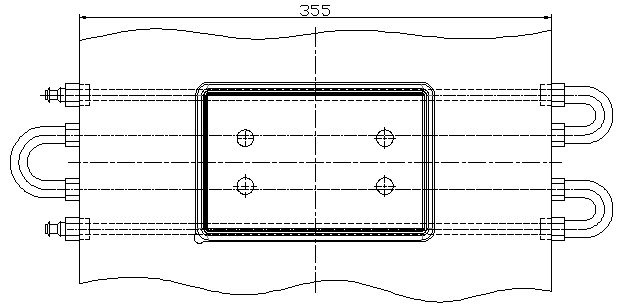

Ekubeni olu yilo lwenzelwe iinxalenye zeplastiki ezincinci kunye neziphakathi, i-mold frame yi-P4-250355-26-Z1 GB / T12556.1-90, kunye ne-B0 × L yesakhelo sokubumba yi-250mm × 355mm.

Umzobo wokubumba umzobo umi ngolu hlobo lulandelayo:

2.7 Uyilo lwecandelo lolwakhiwo

2.7.1Uyilo lwekholamu yesikhokelo

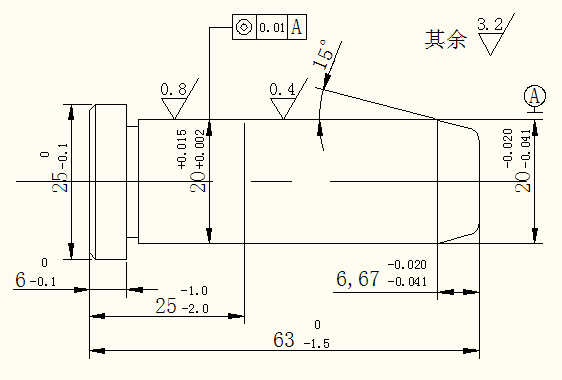

Ububanzi besithuba sesikhokelo ngu-Φ20, kwaye izinto ezikhethiweyo kwisithuba sesikhokelo yintsimbi ye-20, kunye ne-carburizing ye-0.5 ~ 0.8mm kunye nokucima ubunzima be-56 ~ 60HRC.I-Angle e-chamfered eboniswe kumzobo ayikho ngaphezu kwe-0.5 × 450.Isithuba sesikhokelo siphawulwe njenge-Φ20 × 63 × 25 (I) — 20 insimbi GB4169.4 — 84. Ukulungelelaniswa kwe-H7 / m6 yokutshintshwa kwamkelwe phakathi kwenxalenye emiselweyo yekholamu yesikhokelo kunye nethemplate.Esinye isithuba sesikhokelo siphawulwe Φ20×112×32 — 20 steel GB4169.4 — 84.

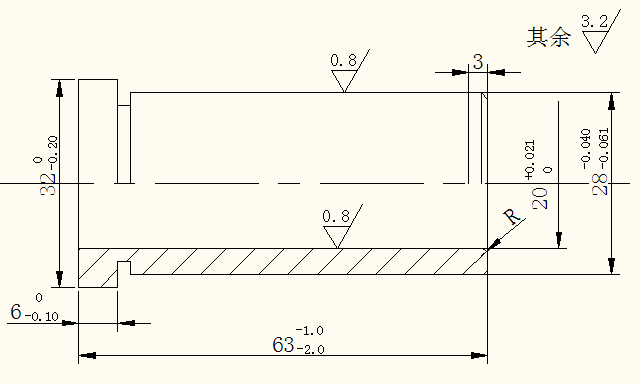

2.7.2Isikhokelo soyilo lwesakhiwo semikhono

Ububanzi bomkhono wesikhokelo ngu-Φ28, kunye nezinto eziphathekayo ze-sleeve yesikhokelo yintsimbi ye-20, i-carburized 0.5 ~ 0.8mm, kunye nobunzima bonyango olucinyiweyo yi-56 ~ 60HRC.I-chamfering eboniswe kumzobo ayikho ngaphezu kwe-0.5 × 450.Umkhono wesikhokelo uphawulwe njenge-Φ20 × 63 (I) — 20 yensimbi GB4169.3 — 84, kunye nokuchaneka kokuchaneka kweposti yesikhokelo kunye nomkhono wesikhokelo ngu-H7 / f7.Omnye umkhono wesikhokelo ophawulwe Φ20 × 50 (I) — 20 intsimbi GB4169.3 — 84.

2.8 Qalisa uyilo lwesixhobo

Indlela yokutyhala iquka ukutyhala, ukusetha ngokutsha kunye nokukhokela.

Ngenxa yokuba iinxalenye zeplastiki zincinci, kwimeko yokuzama ukuqinisekisa umgangatho wembonakalo yamalungu eplastiki, uyilo lwendlela yokuqalisa ithatha intonga ye-ejector ukutyhala ngaphandle iindawo zeplastiki.

Idayagram ecwangcisiweyo yendlela yokuqalisaimi ngolu hlobo lulandelayo:

Ubume kunye neeparamitha zentonga yokutyhalaziboniswe ngezantsi:

Ifom yesakhiwo kunye neeparitha zentonga yokusetha kwakhonaziboniswe ngezantsi:

2.9 Uyilo lwesixokelelwano sokupholisa

Njengoko ukupholisa akufani, inkqubo yokupholisa yomjelo wokupholisa kufuneka ibe kangangoko kunokwenzeka, olu khetho loyilo lwe-4. Umgama wesiteshi ukusuka kumphezulu womgodi ulingana, kwaye i-sprue nayo yomelezwa ukupholisa.Inkqubo yokupholisa ithatha uhlobo lokujikeleza kwe-DC, olunesakhiwo esilula kunye nokulungiswa okufanelekileyo.

Uyilo lwenkqubo yokupholisa ngolu hlobo lulandelayo:

Icandelo lesiThathu:Jonga ubalo lwesitofu sokungunda

3.1.Khangela iiparamitha zenkqubo ehambelanayo yomatshini wokutofa

3.1.1 Qwalasela ubuninzi bomthamo wokutofa

3.1.2 Qwalasela amandla okubamba

3.1.3 Jonga uhambo lokuvula umngundo

3.2.Jonga ubukhulu bodonga olusecaleni kunye nepleyiti esezantsi yecango lexande

3.2.1 Qwalasela ukutyeba kodonga olusecaleni lomngxuma odibeneyo woxande

3.2.2 Qwalasela ukutyeba kwepleyiti esezantsi yomngxuma womphandle wexande

isiphelo

Umyili weqela loMgcini weFreshness u-Xie Master olu yilo luyilwe ikakhulu kuyilo lokungunda lwebhokisi yesidlo sasemini seplastiki, ngokuhlalutya impahla yeplastiki yesigqubuthelo sebhokisi yesidlo sasemini, ulwakhiwo lwamalungu eplastiki kunye nobuchwepheshe, kwaye emva koko kusengqiqweni, ukugqitywa kwenzululwazi yesitofu sokubumba. uyilo.

Umgcini omtsha Iinzuzo zoyilo kukwenza lula umatshini wokubumba inaliti kangangoko kunokwenzeka ukuqinisekisa umgangatho wamalungu eplastiki, unciphise umjikelo wokubumba, iindleko eziphantsi zokuvelisa.Amanqaku abalulekileyo oyilo yinkqubo yokubumba i-injection, i-cavity layout, i-parting surface ekhethiweyo, inkqubo ye-gating, i-ejection mechanism, i-demoulding mechanism, inkqubo yokupholisa, ukukhethwa komatshini wokubumba kunye nokukhangela iiparitha ezifanelekileyo kunye noyilo lwamacandelo aphambili.

Uyilo olukhethekileyo loMgcini weFreshness ilele kuyilo lwenkqubo yokugalela, ukugalela umkhono wesango lenkqubo kunye nomsesane wokumisa kwindawo enye, qinisekisa ubomi bobumba, kunye nokukhethwa kwezinto, ukusetyenzwa, unyango lobushushu kunye nokutshintshwa kulungele;Isango luhlobo oluchanekileyo lwesango, olufuna indawo ephindwe kabini, kwaye i-drawplate yomgama oqingqiweyo isetyenziselwa ukunciphisa ukwahlukana kokuqala.Ulwakhiwo lulula kwaye lunengqiqo.

Ixesha lokuposa: Nov-01-2022